In a recent article on our blog (Link to blog post), we explored the significance of selecting the right sealing materials for Vanadium-based redox flow batteries. Today, we’ll delve into the crucial process of applying these sealings during the production phase of our batteries.

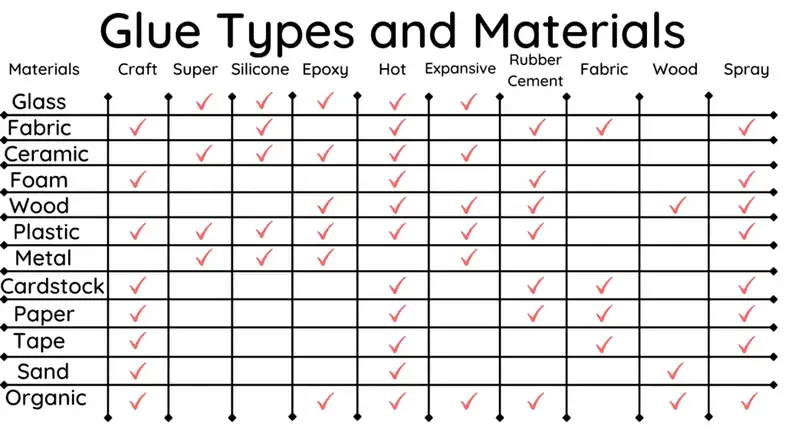

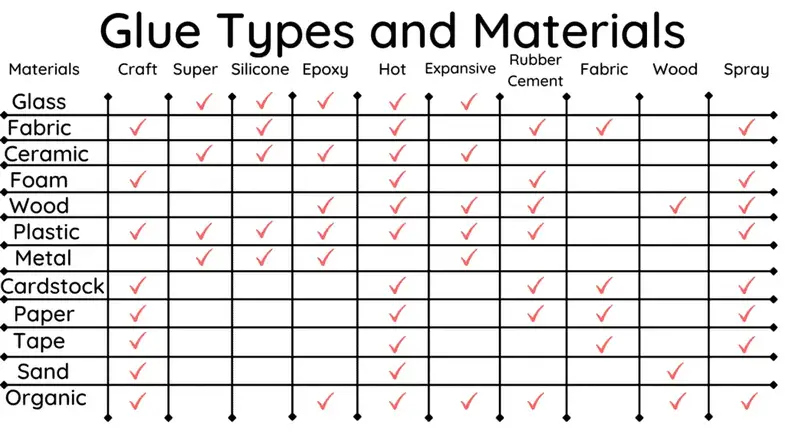

Our approach involves the use of specialized adhesives to securely attach the custom sealing materials to the battery frame. Selecting the appropriate adhesive involves considering several vital factors:

- Compatibility: It’s essential that the adhesive works harmoniously with the frame’s surface material (Polyvinylchloride – PVC) and the sealing material (either FKM or EPDM). This ensures the battery’s integrity, particularly in the event of leaks.

- Temperature Resilience: The adhesive must be robust enough to function reliably across a wide temperature spectrum, ranging from 0 to 50°C. This versatility is key to the battery’s consistent performance in diverse operating conditions.

- Curing Time: We prefer adhesives with longer curing times. This allows for precise and accurate application of the sealant, ensuring optimal alignment and bonding.

- Availability: Having ready access to these adhesives from trustworthy suppliers is essential for maintaining our production schedule without disruptions.

In terms of compatibility, there are numerous adhesive options suitable for our requirements. However, when it comes to resistance against the acidic and oxidizing nature of our electrolytes, epoxy-based adhesives emerge as the top choice.

Source: https://missionmomplex.com/different-kinds-of-glue-types-uses-safety/ accessed on: 28.07.2023

Epoxy adhesives are available in two forms: single-component and two-component systems. The single-component variety cures through heat application, offering flexibility in curing time. Applying higher temperatures can accelerate the curing process, while lower temperatures extend it, providing adaptability based on our production needs.

The good news is that epoxy-based adhesives are readily accessible. Two-component epoxies can be found in local stores, offering convenience for quick procurement. For the single-component variant, specialized online shops are the go-to sources, catering to more specific requirements.

By carefully considering these factors, we ensure that the application of sealing materials in our Vanadium-based redox flow batteries is not only effective but also contributes to the overall durability and efficiency of our products.

ACKNOWLEDGEMENT:

This work was supported by the project: IPCEI_IE_FLOW_BESS_012021